Are pres-ent in many industries including Power Generation and Oil Processing. To if you need an Air Cooled Heat Exchanger solution for a severe service or harsh environment.

Pdf Optimization Of Air Cooled Heat Exchanger Design Using Htri Research And Scientific Innovation Society Rsis International Academia Edu

Learn how from the experts at SRC.

. Progress in forced-air heat exchanger technology is hampered by the fundamental physical. However there are more parameters to be considered in the design of an air-cooled exchanger. Determine the operating temperature between the two fluids 3.

A decision must be made as to what the. Any deviation from this requirement will need the prior approval of the Company. The Basic Design Equation and Overall Heat Transfer Coefficient The basic heat exchanger equations applicable to shell and tube exchangers were developed in Chapter 1.

The temperature difference between the fluid and the wall varies along the length of the heat exchanger. Fast and accurately permitting intensive study and contributing to optimum design in terms of cost and performance. Since the air-cooled heat exchanger is exposed to changing climatic conditions problems of control of the air cooler become relevant.

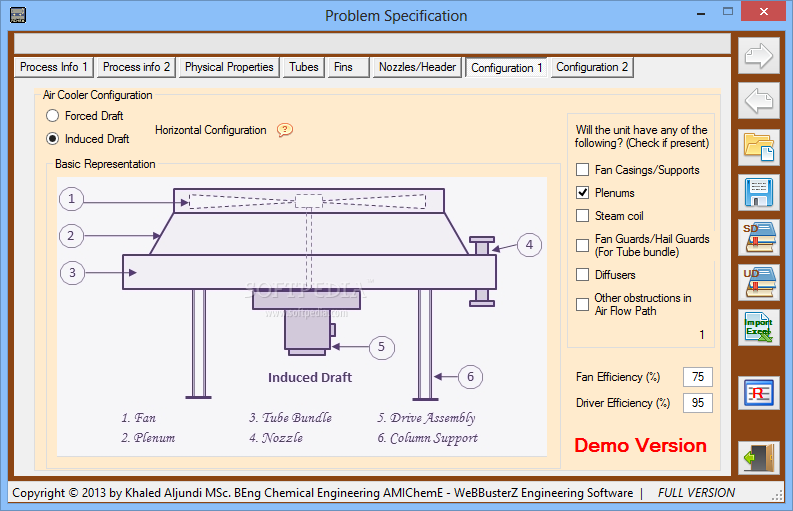

Lower flow speed lower noise. Lectures 19 Applied Heat Transfer CM3110 1232019 3 T outer bulk temperature T inner bulk temperature L BUT. Air cooled heat exchanger calculations excel elusya de.

Heat exchanger coil cooler screw compressor heat. Maximizing belt life means avoiding the following pitfalls. Liquid cooling is able to achieve better heat transfer at much lower mass flow rates.

Select an appropriate Plate Heat Exchanger available in the market for specific use. Our high performance standards continue beyond the fac-. Determine the required Cooling Capacity of the Plate Heat Exchanger 2.

This emphasizes the need for the process engineer to do proper checks himself using a. Construction of Shell-And-Tube Heat Exchangers. This capability combined with the vast experience gained in designing cooling systems for a variety of heat transfer problems allows Paharpur to custom-design and construct air-cooled heat exchangers for nearly all applications.

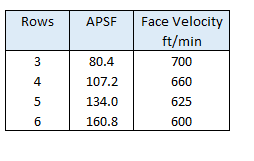

Typical heat exchanger A typical air cooled heat exchanger mechanical components of heat exchanger. Air cooled heat exchanger design slideshare. Our heat exchangers help your system work smarter.

Components may be listed as 1. The economic profitability of an air-cooled heat exchanger depends on the capacity of the finned tubes. Air cooling is limited by specific heat.

Ad Designed and engineered for quality. 01 April 2011 At least two fans shall be provided for each bay. To dissipate large amounts of power a large mass flow rate is needed.

Browse SRC industrial heat exchanger products. The primary objective in the thermal design of heat exchangers is to determine. Here we will cite only those that are immediately useful for design in shell and tube heat exchangers with sensible heat transfer on the shell-side.

Fouling of an air-cooled heat exchanger and alternative design approach. Determining heat transfer coefficients for a finned tube. From dust pollen etc 3 high electrical power consumption related to fan aerodynamic efficiency and 4 heat exchanger cooling capacity limitations i mposed by fan noise.

Tubes with fins as basic component which is made up of carbon steel thru which process fluid at high temperature flow and heat exchange takes place. The air cooled heat exchanger market is highly competitive and manufacturers are tempted to design very tightly knowing that in many cases the actual performance will be hard to check. Identify what types of fluid will be used 4.

PROCESS DESIGN OF AIR COOLED HEAT EXCHANGERS AIR COOLERS PROJECT STANDARDS AND SPECIFICATIONS Page 5 of 19 Rev. Calculations of Heat Exchanger 3. The design of an air-cooled heat exchanger.

Chapter 5 heat exchangers memorial university of. High level run-time integration with Aspen Plus andor Aspen HYSYS allows engineers to rigorously model heat exchanger operation and identify. Proceedings of the 14th IAHR Cooling Tower and Air.

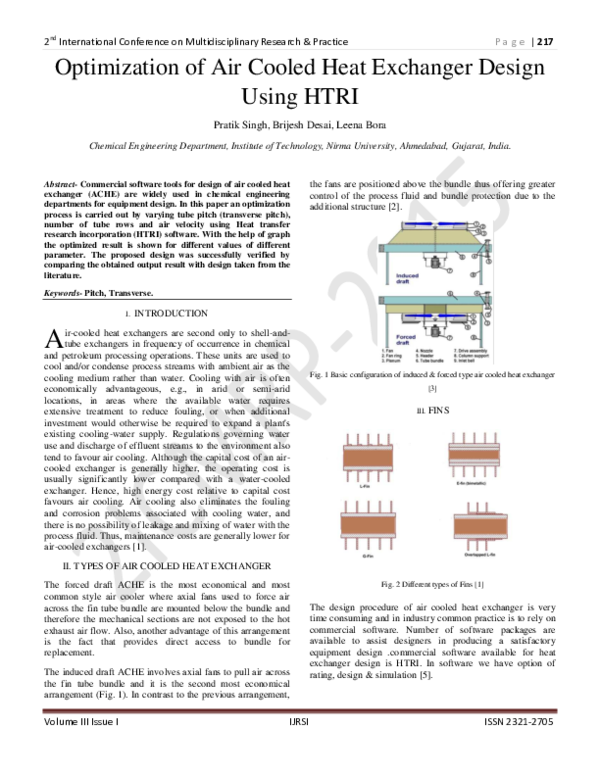

A air cooled heat exchanger is shown in the figure 1. The capacity results from the transfer of the maximum heat exchanged in the smallest possible space while keeping thermodynamic losses on the air side low. Our high pressure capability goes beyond 11000 psig and we offer a variety of materials for high and low temperature applications as well as low noise design options.

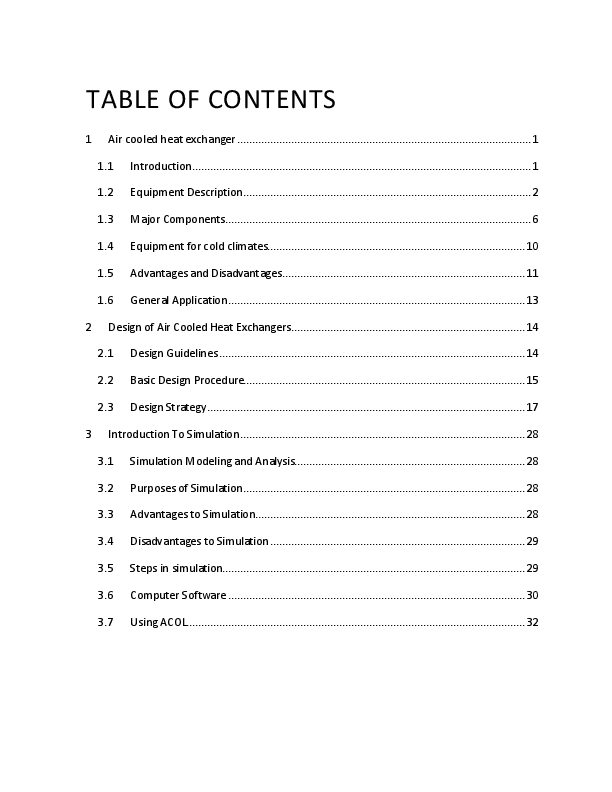

AIR COOLED FIN FAN HEAT EXCHANGER SELECTION SIZING AND TROUBLESHOOTING Kolmetz Handbook Of Process Equipment Design March 2020 Project. Heat transfer enhancement techniques and novel design concepts allow Increase in performance for fixed size andor Weight or conversely Reduction in heat exchanger size andor weight Reduction in size and weight are not the same HX layout in a typical Aircraft Air Conditioning ACS Pack Schematic of a typical single-pass cross-flow. Kolmetz Handbook of Process Equipment Design.

The obvious advantage of an ACHE is that it does not require water which means that plants requiring large. Higher flow speed larger noise. Heat transfer coefficients for air an liquid flows are orders of.

Aspen Shell Tube Exchanger Aspen Plate Exchanger and Aspen Air Cooled Exchanger enable expert and casual users to realize optimum design rating and simulation of their respective exchangers. T1 T2 T1 T2 x The Simplest Heat Exchanger. Incorrect installation practice weak framework and loose mounting bolts are common contributors to drive misalign-ment.

Fans in Various Duties Where for reasons of control an air-cooled heat exchanger. 2 The air-cooled condenser The air-cooled condenser is a steam-air heat exchanger composed by several modules such as that sketched by fig. Apply at least 10 safety margin on the selection 6.

Heat Transfer Applications 4. 2 performance degradation due to heat exchanger fouling eg. See that bolts are properly.

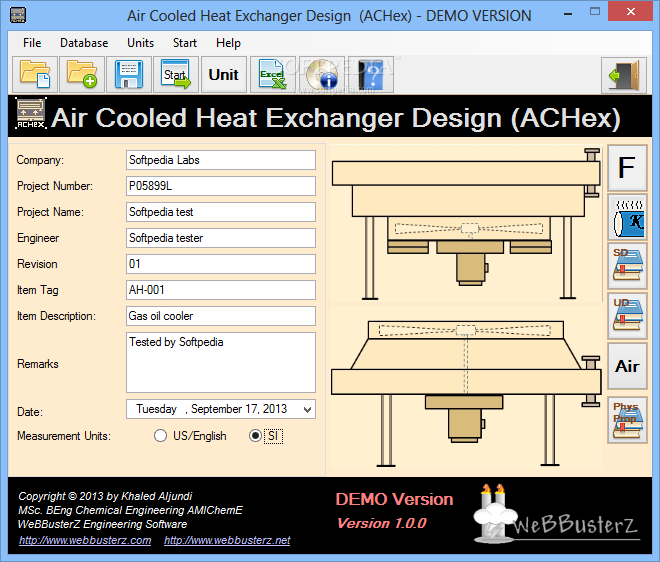

Estimate the temperature to which the water is cooled if the brine enters at -8C and leaves at 10C. Air Cooled Heat Exchanger Design Software perform April 26th 2019 - Air cooled heat exchanger design software ACHex has been built to perform all require thermal design calculations for this type of heat exchangers Air Cooled Heat Exchanger Software Features ACHex This software supports liquid and gas services only the software doesnt. DoublePipe Heat exchanger counter current cold less cold less hot hot.

An ACHE is a device for rejecting heat from a fluid directly to ambient airThis is in contrast to rejecting heat to water and then rejecting it to air as with a shell and tube heat exchanger and a wet cooling tower system. Air cooled heat exchanger design free download and. Account the design and operating data of a condenser installed in a 400 MW combined cycle power plant still operative in the Italian electricity market.

Air Cooled Heat Exchanger Design 2 0 0 1 Free Download

Download Air Cooled Heat Exchanger Design 1 0 0 0

Pdf Acc Design Calculation Sudhir Bisen Academia Edu

Shortcut Sizing For Air Cooled Heat Exchanger

Download Air Cooled Heat Exchanger Design 1 0 0 0

Heat Exchanger Calculations And Design With Excel Spreadsheet Templates Bright Hub Engineering

0 comments

Post a Comment